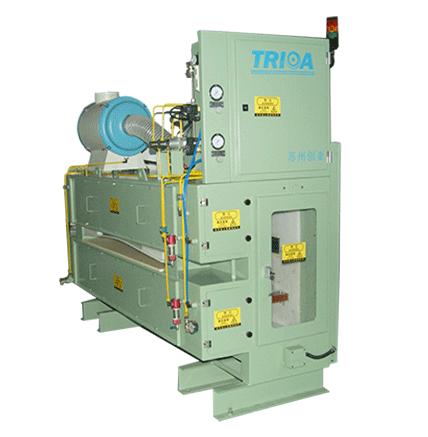

Product Description:

TRIOA™ DOS oil horizontal electrostatic oiler (called H.E.S.O lub model) was designed for coating dos oil on the surface of continuous metal strip and sheet. DOS oil have a food grade character and it is environmental and removed easily.Good anti-rust and lubricity makes dos oil used widely in Blank Plate, Cold Rolling Mill, Continuous Galvanizing Line, Recoiling & Slitting Line, Aluminum foil, PS plate and so on. State-of- the-art Nozzles-atomizer techniques can charge the mist during atomization and electrostatic absorption, which making it possible to coat uniform without blocking and skipping and lowest coating weight up to 20mg/m² per side by strip travel horizontally.

1. The nozzle is located in a semi-closed atomizing chamber which is free of blockage problem or coating

skips by harsh environment. Never oil trickling in the shutdown state.

2.State-of- the-art Nozzles-atomizer & electrostatic adsorption techniques make oil distribution even and

minimum 20 mg/sqm/side oil coating possible.

3. Double couple electrodes with discharge point make electrostatic force more intensive, avoiding oil mist spilling.

4. Coating width is adjustable, Preventing blocking of nozzles induced by frequent waste oil circulation

and avoiding oil deterioration;

5. Coatings are applied using non-contact techniques. Uniformity is not dependent upon strip irregularities.

6. Easy-operating on local touch screen or remote central terminal control enables extremely simple operation.

7. Core components and parts are imported with the original packaging; ensuring product performance reliability

and prolonging service life.

8. Almost achieving less routine manual maintenance and maintenance cost.

• Input voltage: 380 VAC/50HZ/3PH @15.0 Amps maximum

• HVPS output: 60KVDC @ 5mA

• Coating width: 300~2400mm

• Strip speed: 30~650 m/min

• Coating weight: 20~300 mg/m² per side

• Oil film tolerance: 4 m³/min @ 2 bar

• Coating material: +/- 10%

BP line, PS line, CRM, CGL & Printed plate line.